Highlight High Power Direct Diode Laser

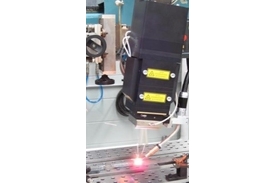

4 kW, 8 kW, and 10 kW Direct-Diode laser power with flexible beam shape, ideal for heat treating and cladding applications.

|

| Highlight D Series |

Primary Beam Shapes: Line Beam

Secondary Beam Shape: Rectangular/Square Beam

|

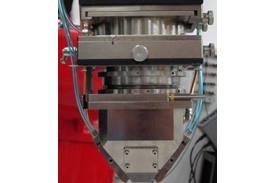

| Cladding Nozzle | Beam Shaping Optics | ||

|

|

|

|

| Powder-Based Laser Cladding | Hot-Wire Laser Cladding | ID Cladding Nozzle | Heat Treatment |

|

|

|

|